Introduction to Roll Shaping Machines

Roll shaping machines are versatile industrial equipment used to manipulate metal sheets or coils into desired shapes. These machines are commonly used in various industries such as automotive, aerospace, and construction. They offer precision and efficiency in forming metal, making them essential tools in manufacturing processes.

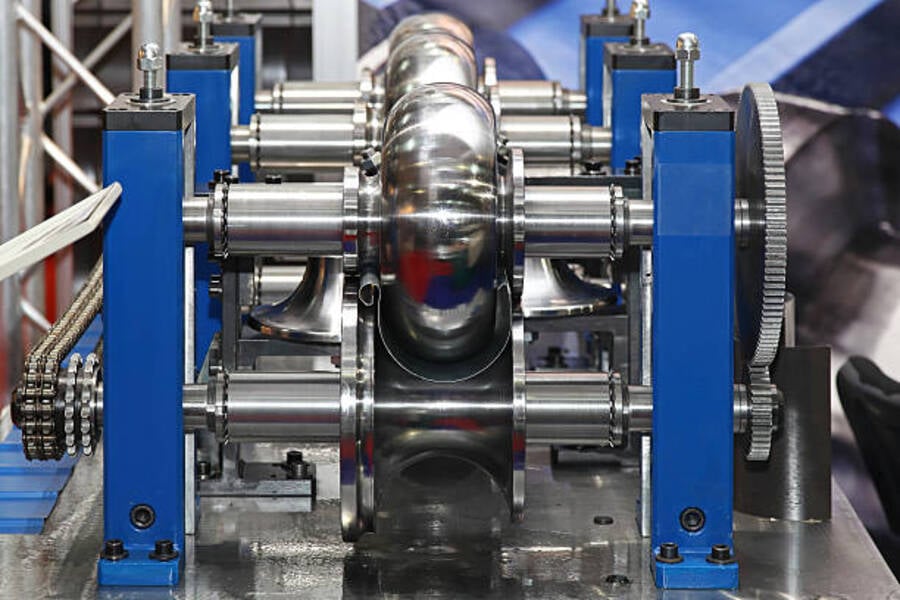

Working Principle of Roll Shaping Machines

Roll shaping machines operate on the principle of bending metal sheets or coils between a set of rollers to achieve the desired shape. The rollers can be adjusted to apply different levels of pressure, allowing for precise control over the forming process. This results in accurate and uniform shapes that meet the required specifications.

Types of Roll Shaping Machines

There are several types of roll shaping machines available, each designed for specific shaping tasks. Some common types include pyramid type, initial-type, and symmetrical type roll shaping machines. These machines vary in their capabilities and features, catering to the diverse needs of different industries.

Advantages of Using Roll Shaping Machines

One of the key advantages of roll shaping machines is their ability to produce complex shapes with high precision. They also offer increased production efficiency and cost-effectiveness compared to manual forming methods. Additionally, roll shaping machines can handle a wide range of materials, making them versatile equipment for various manufacturing processes.

Applications of Roll Shaping Machines

Roll shaping machines find applications in a wide range of industries, including automotive body manufacturing, HVAC duct fabrication, and furniture production. They are used to create components such as panels, tubes, and profiles with high accuracy and repeatability. These machines play a crucial role in streamlining production processes and ensuring consistency in product quality.

Key Features to Consider

When choosing a roll shaping machine for your manufacturing needs, it is essential to consider certain key features. These include the machine's capacity, speed, precision, and flexibility. Additionally, factors such as the material thickness and type of shapes required should also be taken into account to select the most suitable machine for the job.

Maintenance and Safety Tips

Proper maintenance of roll shaping machines is crucial to ensure their optimal performance and longevity. Regular inspection of components, lubrication, and alignment checks are essential to prevent breakdowns and ensure safe operation. Operators should also follow safety guidelines and receive training on using roll shaping machines to avoid accidents.

Future Trends in Roll Shaping Technology

Advancements in roll shaping technology are continuously evolving to meet the changing demands of the manufacturing industry. Integrated software systems, automated controls, and artificial intelligence are some of the trends shaping the future of roll shaping machines. These innovations aim to enhance productivity, accuracy, and efficiency in metal forming processes.

Environmental Impact and Sustainability

As the focus on sustainability and environmental conservation grows, manufacturers are seeking ways to reduce the carbon footprint of their operations. Roll shaping machines offer an eco-friendly solution by optimizing material usage, minimizing waste, and enhancing energy efficiency. By adopting sustainable practices in metal forming processes, companies can contribute to a greener future.

Conclusion

In conclusion, roll shaping machines play a vital role in modern manufacturing processes by offering precision, efficiency, and versatility in metal forming. From automotive components to architectural structures, these machines are essential tools for shaping metal into various products. By understanding the capabilities and benefits of roll shaping machines, manufacturers can improve their production processes and deliver high-quality products to meet market demands.

Quote Inquiry

Contact Us