Introduction: Understanding the Versatile Roll Former Machine

The roll former machine is a versatile piece of equipment used in various industries for metalworking processes, such as shaping and bending metal sheets into specific profiles. This machine is widely employed in manufacturing and construction sectors, offering immense benefits in terms of efficiency, precision, and cost-effectiveness. In this comprehensive guide, we will explore the different aspects of roll former machines and their applications.

1. What is a Roll Former Machine?

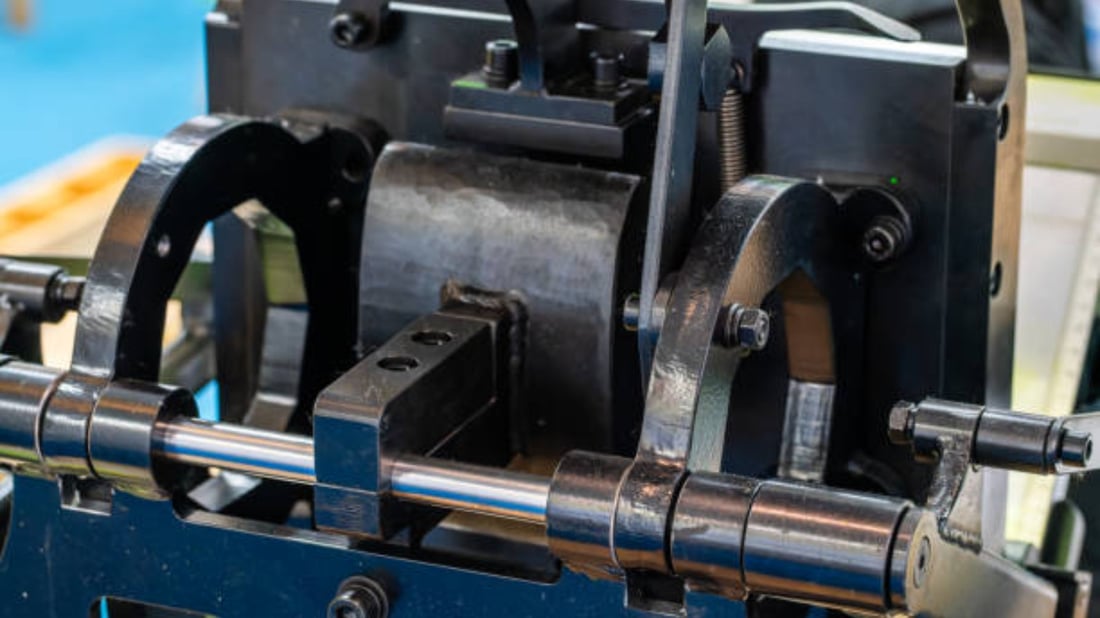

A roll former machine, also known as a roll forming machine, is a mechanical device used to continuously shape metal strips or sheets into desired profiles. It consists of a series of rollers that gradually bend and form the metal as it passes through the machine. The rollers are precisely positioned to create specific shapes, such as channels, angles, tubes, and more. Roll former machines are typically computer-controlled, allowing for precise control over the forming process.

2. How Does a Roll Former Machine Work?

The roll forming process begins with feeding a metal strip or sheet into the roll former machine. The strip is then guided through a series of rollers, which gradually bend and shape the metal. Each roller in the machine is designed to perform a specific bending or forming action. As the metal passes through the rollers, it undergoes continuous deformation until it reaches the desired profile. The formed metal is then cut to the required length and collected for further processing or assembly.

3. Advantages of Using a Roll Former Machine

Roll former machines offer numerous advantages over traditional metalworking methods. Here are some key benefits:

- Efficiency: Roll former machines can produce large quantities of accurately formed metal profiles in a short amount of time, significantly increasing productivity.

- Precision: The computer-controlled nature of roll former machines ensures precise shaping and bending of metal, leading to consistent and high-quality results.

- Versatility: Roll former machines can create a wide range of profiles, allowing for flexibility in design and manufacturing.

- Cost-effectiveness: By minimizing material waste and reducing labor costs, roll former machines offer a cost-effective solution for metal shaping and forming processes.

4. Applications of Roll Former Machines

Roll former machines find application in various industries due to their versatility and efficiency. Some common uses include:

- Construction: Roll former machines are widely used in the construction industry for manufacturing metal roofing, wall cladding, and structural components.

- Automotive: These machines are employed to produce automotive body parts, such as door frames, window channels, and fender profiles.

- Appliances: Roll former machines are utilized in the production of appliance components, including refrigerator shelves, dishwasher racks, and oven panels.

- Furniture: The furniture industry benefits from roll former machines for creating metal frames, supports, and decorative profiles.

5. Factors to Consider When Choosing a Roll Former Machine

When selecting a roll former machine for your specific needs, there are several factors to consider:

- Material Compatibility: Ensure that the machine is capable of handling the type and thickness of metal you intend to work with.

- Profile Flexibility: Look for a machine that offers a wide range of profile options, allowing for versatility in your manufacturing processes.

- Speed and Efficiency: Consider the production speed and efficiency of the machine to ensure it meets your desired output requirements.

- Quality and Precision: Check the machine's reputation for producing high-quality, precise profiles consistently.

6. Maintenance and Care for Roll Former Machines

Proper maintenance and care are essential for the longevity and optimal performance of roll former machines. Here are some maintenance tips:

- Regular Cleaning: Keep the machine clean from debris, dust, and metal shavings that could affect its performance.

- Lubrication: Apply lubricants to the moving parts of the machine to minimize friction and ensure smooth operation.

- Inspection: Regularly inspect the machine for any signs of wear, damage, or misalignment, and address issues promptly.

- Training: Train operators on proper machine operation and safety protocols to prevent accidents and maximize efficiency.

7. Latest Technological Advancements in Roll Former Machines

The roll former machine industry continues to evolve with technological advancements. Some recent innovations include:

- Computer Numerical Control (CNC): CNC technology allows for precise control and automation of the roll forming process, enhancing efficiency and accuracy.

- Quick Change Systems: These systems enable rapid tooling changes, reducing downtime and increasing production flexibility.

- Integration with CAD/CAM Software: Roll former machines can now be seamlessly integrated with computer-aided design (CAD) and computer-aided manufacturing (CAM) software for streamlined production workflows.

8. Future Trends and Outlook for Roll Former Machines

The future of roll former machines looks promising, with several trends shaping the industry:

- Industry 4.0 Integration: Roll former machines are expected to be integrated into smart factories, leveraging automation, data exchange, and real-time analytics.

- Increased Customization: As customer demands for unique and personalized products rise, roll former machines will need to adapt to offer more customization options.

- Environmentally Friendly Solutions: Manufacturers are exploring eco-friendly materials and energy-efficient processes to reduce the environmental impact of roll former machines.

9. Leading Manufacturers of Roll Former Machines

Several reputable manufacturers produce high-quality roll former machines. Some of the leading companies include:

- Bradbury Group: Known for their extensive range of roll former machines and innovative solutions for various industries.

- Samco Machinery: Offers a wide range of roll forming equipment, including custom solutions tailored to specific customer needs.

- Formtek, Inc.: Specializes in roll forming systems and related equipment, delivering reliable and efficient solutions.

10. Conclusion: Harnessing the Power of Roll Former Machines

Roll former machines have revolutionized the metalworking industry, offering unmatched efficiency, precision, and versatility. Whether you are in the construction, automotive, or furniture industry, a roll former machine can significantly streamline your manufacturing processes. By understanding the various aspects of roll former machines, you can make informed decisions and leverage this technology to stay ahead in today's competitive market.