Introduction to Hydraulic Post Cutting

Hydraulic post cutting plays a crucial role in the roll forming process. It is a method used to cut the formed material into specific lengths. This process requires precision and efficiency to ensure the final product meets the required specifications.

Benefits of Hydraulic Post Cutting

One of the main benefits of

hydraulic post cutting in roll forming lines is the ability to achieve clean and accurate cuts. This method allows for high-speed cutting without compromising the quality of the end product. Additionally, hydraulic post cutting is a cost-effective solution for manufacturers looking to improve their production processes.

How Hydraulic Post Cutting Works

Hydraulic post cutting involves the use of a hydraulic cylinder to drive the cutting blade through the material. The cutting blade can be adjusted to different lengths, allowing for flexibility in the cutting process. This method is ideal for cutting a wide range of materials, including steel, aluminum, and copper.

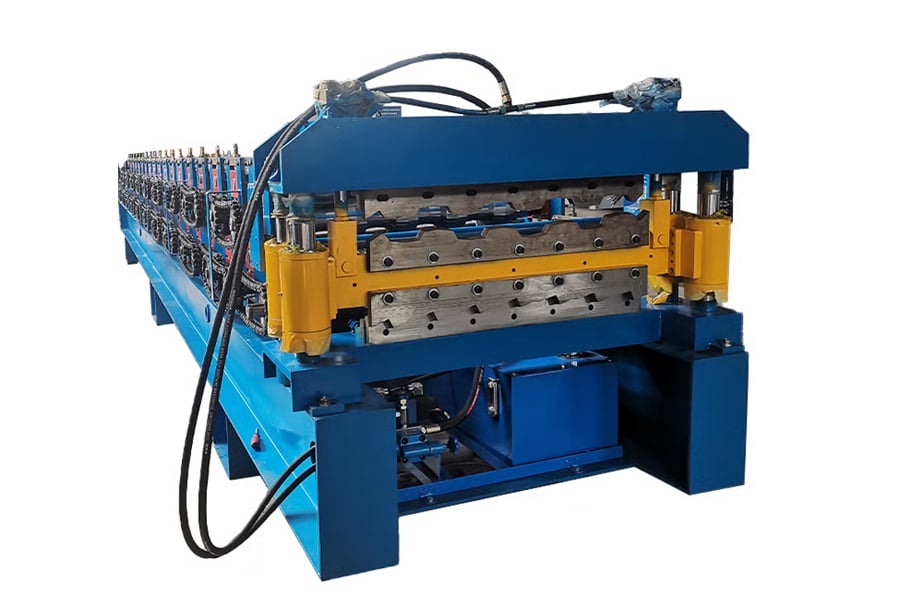

Integration with Roll Forming Lines

Hydraulic post cutting can be seamlessly integrated into existing roll forming lines. This allows manufacturers to enhance their production capabilities without the need for major equipment changes. By incorporating hydraulic post cutting, manufacturers can improve efficiency and reduce waste in their production processes.

Accuracy and Precision

One of the key advantages of hydraulic post cutting is its ability to deliver precise and accurate cuts. This is essential in the manufacturing industry, where even minor deviations can affect the overall quality of the final product. Hydraulic post cutting ensures that each piece is cut to the exact specifications, resulting in consistent and high-quality products.

Customization and Flexibility

Hydraulic post cutting offers manufacturers the flexibility to customize their cutting process according to their specific requirements. The cutting length, speed, and depth can be easily adjusted to accommodate different materials and production needs. This level of customization allows manufacturers to optimize their production processes for maximum efficiency.

Enhancing Productivity

By incorporating hydraulic post cutting into roll forming lines, manufacturers can significantly enhance their productivity levels. This method allows for faster cutting speeds and reduced downtime, resulting in increased output and improved overall efficiency. With hydraulic post cutting, manufacturers can meet customer demands and deadlines more effectively.

Quality Control and Consistency

Maintaining consistent quality is essential in the manufacturing industry. Hydraulic post cutting ensures that each piece is cut with precision, resulting in uniformity across all products. This level of quality control enhances the reputation of manufacturers and fosters customer trust in their products.

Cost-Effectiveness and ROI

Implementing hydraulic post cutting in roll forming lines is a cost-effective investment for manufacturers. The efficiency and speed of this cutting method can lead to significant cost savings over time. Additionally, the improved productivity and quality control can result in a higher return on investment for manufacturers.

Conclusion

In conclusion, hydraulic post cutting is a valuable tool in the roll forming industry. It offers a wide range of benefits, including precision cutting, customization options, and enhanced productivity. By integrating hydraulic post cutting into their production processes, manufacturers can improve efficiency, quality, and overall profitability.

Quote Inquiry

contact us