The Versatility of a Purlin Roll Forming Machine

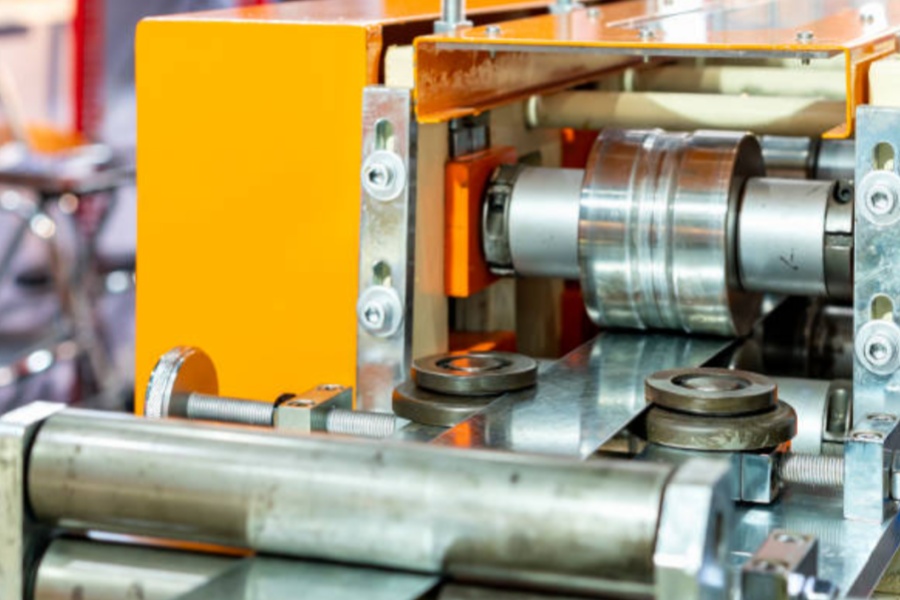

If you're looking for a way to streamline your manufacturing process and boost your productivity, investing in a purlin roll forming machine might be the ideal solution. These machines are automated manufacturing tools that fabricate a range of metal profiles and shapes. They are built to precision and engineered to meet specific product and production needs. If you're curious about the many potential uses of a purlin roll forming machine, read on for a closer look at the top ten applications:

1. Roof Purlins

One of the most common uses for a purlin roll forming machine is the creation of roof purlins. These are horizontal members that span across a building's roof and provide support for the roofing panels. With a purlin roll forming machine, you can create purlins of various sizes, shapes, and thicknesses to meet the specific requirements of your project.

2. Wall Purlins

In addition to roof purlins, a purlin roll forming machine can also be used to fabricate wall purlins. These vertical members are attached to the building frame and provide support for the wall cladding. As with roof purlins, wall purlins come in a range of sizes and shapes, making a purlin roll forming machine ideal for the job.

3. Floor Joists

For multi-story buildings, a purlin roll forming machine can be used to create floor joists. These are horizontal elements that support the flooring system of upper levels. A purlin roll forming machine can produce floor joists that are engineered to support the specific loads and span requirements of your project.

4. Framing Members

In addition to purlins and joists, a purlin roll forming machine can be used to create a range of framing members, including studs, tracks, and channels. These are vertical and horizontal elements that form the building frame and provide structural support.

5. Custom Shapes

With a purlin roll forming machine, you're not limited to standard shapes and profiles. These machines can create custom shapes and designs to meet your unique manufacturing needs. Whether you require a complex profile, a decorative trim, or a simple bend, a purlin roll forming machine can do the job.

6. Solar Panel Support Structures

Because of their ability to create custom shapes and profiles, purlin roll forming machines are often used to manufacture solar panel support structures. These structures are designed to hold solar panels in place and protect them from weather and other environmental factors.

7. Agricultural Structures

A purlin roll forming machine can also be used to fabricate a range of agricultural structures, including barns, sheds, and greenhouses. These structures require a variety of framing elements, and a purlin roll forming machine can efficiently produce all the necessary components according to exact specifications.

8. Industrial Structures

For industrial buildings such as factories and warehouses, a purlin roll forming machine can create the framing members needed to support the structure. From columns and beams to framing for equipment and machinery, a purlin roll forming machine can ensure precision and consistency in manufacturing.

9. Modular Buildings

Modular buildings are becoming more and more popular in the construction industry due to their ease of assembly and lower costs. A purlin roll forming machine can manufacture the components needed for modular buildings, including framing elements, roofing and cladding systems, and more.

10. Vehicle Components

Finally, a purlin roll forming machine can also be used to create components for vehicles, such as roof racks and trailer frames.

Conclusion

As you can see, there are many potential uses for a purlin roll forming machine. Whether you're manufacturing components for buildings, solar panels, or vehicles, a purlin roll forming machine can provide quick and efficient results with precision and accuracy. By investing in this powerful manufacturing tool, you can streamline your operations and stay competitive in your industry.