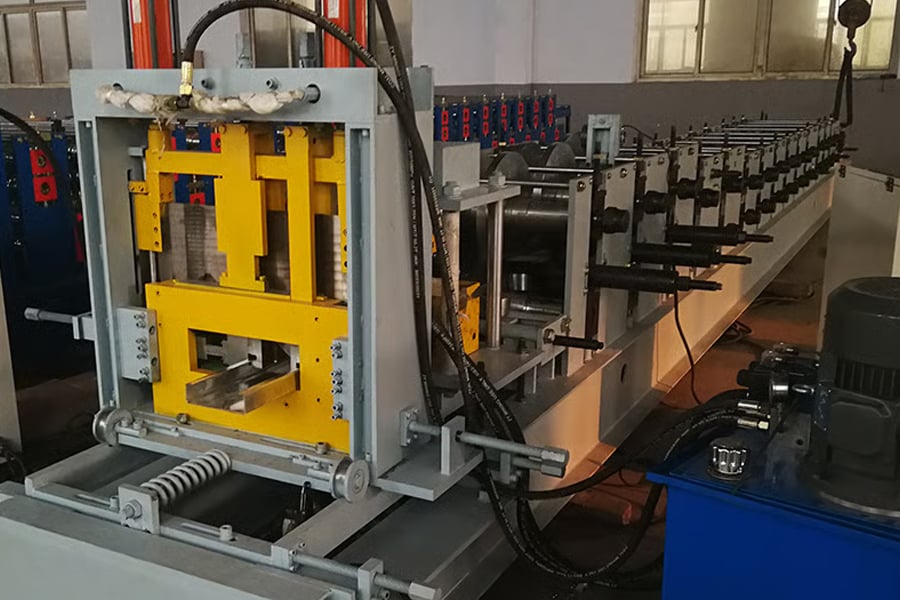

Gutter machine rollers play a crucial role in the seamless gutter installation process. These rollers are the components of a gutter machine that shape the metal coil into the desired gutter profile. The quality and efficiency of the rollers directly impact the overall functionality and durability of the gutters.

Types of Gutter Machine Rollers

There are different types of gutter machine rollers designed for specific gutter profiles such as K-style, half-round, and box gutters. The rollers are made from high-quality materials like steel or aluminum to ensure longevity and precision in shaping the gutters. Understanding the type of gutter profile you are working with is essential in selecting the appropriate rollers for the job.

How Gutter Machine Rollers Work

Gutter machine rollers are powered by the gutter machine's motor, which feeds the metal coil through the rollers. As the metal passes through the rollers, they apply pressure to shape the metal into the desired gutter profile. The precision and smoothness of the rollers' operation are essential for creating seamless gutters that fit perfectly along the roofline.

Benefits of High-Quality Gutter Machine Rollers

Investing in high-quality gutter machine rollers can significantly improve the efficiency and accuracy of gutter installation. Quality rollers ensure consistent shaping of the gutter profile, reducing the chances of leaks or misalignments in the gutter system. Additionally, durable rollers can withstand the wear and tear of continuous use, providing long-lasting performance.

Importance of Maintenance for Gutter Machine Rollers

Proper maintenance of gutter machine rollers is essential to ensure their longevity and performance. Regular cleaning and lubrication of the rollers help prevent build-up of debris or rust that can interfere with the shaping process. Inspecting the rollers for any signs of wear or damage and replacing them as needed is crucial for maintaining the quality of gutter installations.

Factors to Consider When Choosing Gutter Machine Rollers

When selecting gutter machine rollers, consider factors such as the material of the rollers, the type of gutter profile you are working with, and the compatibility with your gutter machine. It is important to choose rollers that are durable, precise, and easy to maintain to achieve the best results in seamless gutter installation.

Common Issues with Gutter Machine Rollers

Some common issues that may arise with gutter machine rollers include warping, bending, or uneven shaping of the metal coil. These issues can result in poorly formed gutters that do not function properly or fit securely. Regular inspection and maintenance of the rollers can help identify and address these issues before they affect the gutter installation.

Benefits of Upgrading Gutter Machine Rollers

Upgrading to high-performance gutter machine rollers can enhance the efficiency and quality of gutter installation projects. Modern rollers are designed to provide smoother operation, increased precision, and reduced downtime during the installation process. Investing in quality rollers can ultimately save time and costs while delivering superior results.

Training on Using Gutter Machine Rollers

Proper training on the use of gutter machine rollers is essential for efficient and safe gutter installation. Operators should be familiar with the operation of the gutter machine and understand how to adjust the rollers for different gutter profiles. Training programs can help improve skills and knowledge in handling gutter machine rollers effectively.

Conclusion

Gutter machine rollers are fundamental components in seamless gutter installation, shaping the metal coil into precise gutter profiles. Investing in high-quality rollers, proper maintenance, and operator training are crucial for achieving efficient and durable gutter installations. By understanding the importance and function of gutter machine rollers, professionals can enhance the quality of their gutter projects.

Quote Inquiry

contact us