The Basics of sheet metal roll forming

Sheet metal roll forming is a highly efficient and cost-effective manufacturing process used to shape flat sheets of metal into complex, customized profiles. This technique involves passing the metal through a series of rollers, which gradually shape it into the desired form. With its versatility and ability to produce consistent and high-quality results, sheet metal roll forming has become a preferred method for various industries.

The Roll Forming Process

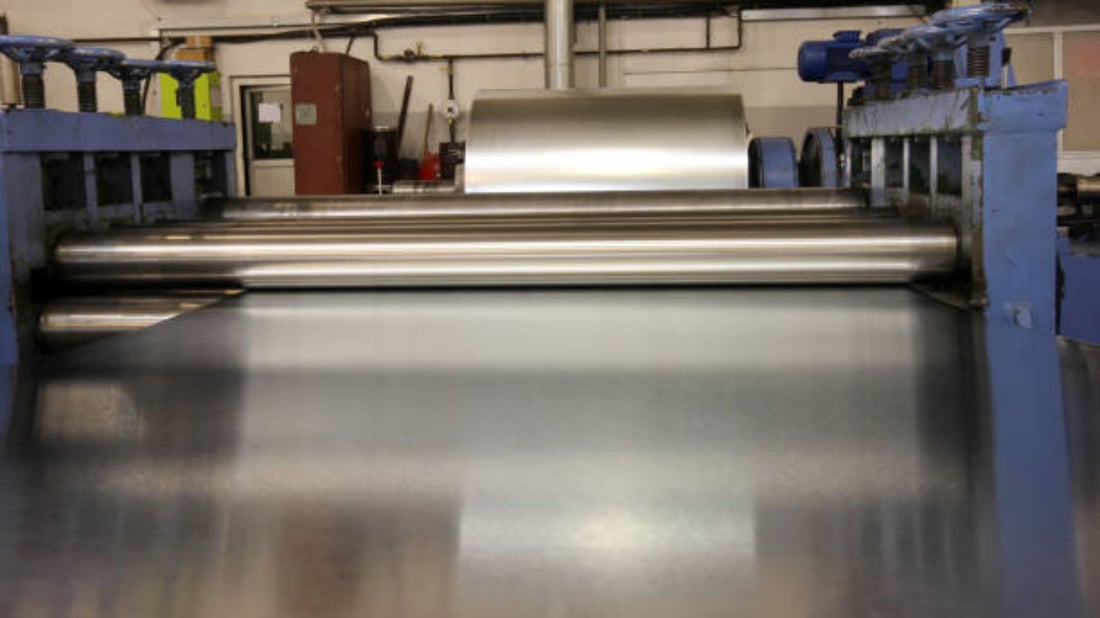

The roll forming process begins with a flat sheet of metal, commonly made of steel, aluminum, or stainless steel. The sheet is fed into a set of rollers, each with a specific profile. As the sheet passes through the rollers, it is gradually bent and formed into the desired shape. The rollers are designed to progressively change the shape of the metal, allowing for the creation of complex profiles with precise dimensions.

Advantages of Sheet Metal Roll Forming

Sheet metal roll forming offers several advantages over other metal forming techniques:

- Cost-effective: Roll forming is a highly efficient process that requires minimal labor and tooling costs.

- High production speed: Roll forming machines can operate at high speeds, allowing for the rapid production of large quantities of parts.

- Consistency and accuracy: The use of rollers ensures consistent and precise shaping of the metal, resulting in parts with tight tolerances.

- Design flexibility: Roll forming allows for the creation of complex profiles with varying thicknesses and shapes, offering designers greater flexibility in their product designs.

- Metal utilization: The roll forming process minimizes waste by efficiently utilizing the entire length of the metal sheet.

Applications of Sheet Metal Roll Forming

Sheet metal roll forming finds applications in various industries, including:

- Automotive: Roll-formed components are used in the automotive industry for body panels, structural reinforcements, and trim parts.

- Construction: Roll-formed profiles are commonly used in the construction of buildings, including roofing, siding, and framing systems.

- Appliances: Roll-formed parts are found in appliances such as refrigerators, ovens, and washing machines.

- Furniture: Roll-formed metal is used in the manufacturing of furniture, including shelving systems and office partitions.

- Electronics: Roll forming is applied in the production of electronic enclosures, racks, and cabinets.

The Importance of Tooling in Roll Forming

Tooling plays a crucial role in sheet metal roll forming. The design and quality of the roll forming tools greatly influence the final product's accuracy and quality. The tooling includes the rollers, which shape the metal, as well as other components such as guides, spacers, and press dies. Proper tooling design and maintenance are essential to ensure consistent and reliable production.

Quality Control in Sheet Metal Roll Forming

Ensuring the quality of roll-formed parts is vital in any manufacturing process. In sheet metal roll forming, quality control measures include:

- Dimensional inspections: Regular checks are performed to verify that the formed parts meet the specified dimensions and tolerances.

- Material testing: The metal used in roll forming is tested for its mechanical properties, such as strength and ductility, to ensure it meets the required standards.

- Visual inspections: The surface quality and finish of the roll-formed parts are visually inspected to identify any defects or imperfections.

- Process monitoring: Continuous monitoring of the roll forming process helps identify any deviations or issues that may affect the quality of the parts.

Challenges in Sheet Metal Roll Forming

While sheet metal roll forming offers numerous advantages, it also presents certain challenges:

- Material limitations: Roll forming is best suited for ductile materials such as steel and aluminum. Brittle materials may crack or break during the forming process.

- Complex profiles: Creating complex profiles with tight radii or intricate shapes can be challenging and may require specialized tooling.

- Setup time: Setting up a roll forming machine for a new profile can be time-consuming, especially if it requires significant adjustments or tooling changes.

- Surface finish: Achieving a consistent surface finish across the entire length of a roll-formed part can be difficult, especially for materials with a high surface reflectivity.

Future Trends in Sheet Metal Roll Forming

The field of sheet metal roll forming continues to evolve, driven by technological advancements and industry demands. Some emerging trends include:

- Advanced automation: The integration of robotics and artificial intelligence is streamlining the roll forming process, increasing efficiency and reducing human error.

- Lightweight materials: With the growing emphasis on lightweighting, roll forming is being adapted to process advanced materials such as composites and high-strength alloys.

- Customization: Manufacturers are increasingly offering customized roll-formed profiles, allowing designers to create unique and innovative products.

- Energy efficiency: Efforts are being made to optimize the energy consumption of roll forming machines, reducing the environmental impact of the manufacturing process.

Conclusion

Sheet metal roll forming is a versatile and efficient manufacturing process with numerous benefits. Its ability to shape flat sheets of metal into complex profiles makes it indispensable in various industries. With proper tooling design, quality control measures, and ongoing advancements, sheet metal roll forming is poised to remain a dominant method for producing high-quality, customized metal components.