Introduction: The Rise of rolling shutter machines

Rolling shutters have become an integral part of modern buildings, offering security and protection against various elements. With the advancement of technology, the manufacturing process of rolling shutters has evolved significantly. One of the key innovations in this industry is the rolling shutter machine, which has revolutionized the way shutters are produced. In this article, we will explore the various aspects of rolling shutter machines and how they have transformed the shutter industry.

1. Understanding Rolling Shutter Machines

Rolling shutter machines are specialized equipment designed for the production of high-quality rolling shutters. These machines are equipped with advanced mechanisms that automate the manufacturing process, resulting in efficient and consistent production. They are capable of producing different types and sizes of rolling shutters, catering to the diverse needs of customers.

2. Benefits of Using Rolling Shutter Machines

Investing in a rolling shutter machine has numerous advantages for manufacturers. Firstly, these machines significantly reduce labor costs by automating the majority of the production process. Additionally, they ensure precise and accurate measurements, leading to consistent and reliable shutter production. Moreover, rolling shutter machines enhance production capacity, enabling manufacturers to meet increasing demands efficiently.

3. Types of Rolling Shutter Machines

There are various types of rolling shutter machines available in the market, each designed for specific purposes. Some common types include manual rolling shutter machines, automatic rolling shutter machines, and motorized rolling shutter machines. Manual machines require manual intervention at different stages of production, while automatic and motorized machines offer higher levels of automation.

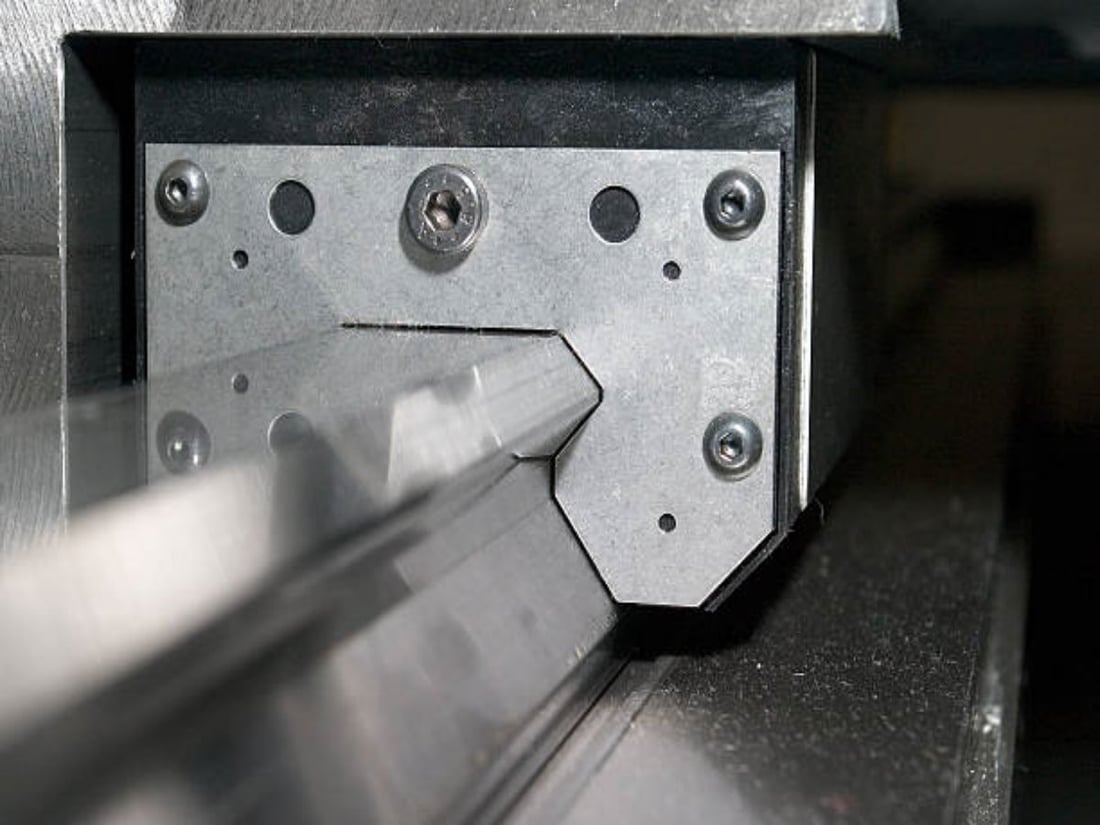

4. Components of a Rolling Shutter Machine

A rolling shutter machine consists of several essential components that work together to produce high-quality shutters. These components include a decoiler, leveling machine, feeding guide, roll forming machine, cutting device, and control system. Each component plays a crucial role in the overall functioning of the machine, ensuring smooth and efficient production.

5. The Roll Forming Process

The roll forming process is a key aspect of rolling shutter machine operation. It involves the continuous shaping of a metal strip into the desired profile. The metal strip passes through a series of rollers, which gradually shape it according to the predetermined design. This process ensures the precise dimensions and uniformity of the rolling shutter components.

6. Customization and Flexibility

Rolling shutter machines offer a high degree of customization and flexibility in the production process. Manufacturers can easily adjust the machine settings to produce shutters of different sizes, designs, and materials. This enables them to cater to the unique requirements of customers and offer a wide range of options in the market.

7. Ensuring Quality and Durability

With the use of rolling shutter machines, manufacturers can ensure the production of high-quality and durable rolling shutters. The automated process eliminates human errors and inconsistencies, resulting in precise measurements and uniform product quality. Additionally, these machines are designed to handle various materials, including steel and aluminum, ensuring the durability of the shutters.

8. Increasing Efficiency and Productivity

Rolling shutter machines have significantly increased the efficiency and productivity of shutter manufacturing. The automation of the production process reduces the time required for manufacturing, enabling manufacturers to produce a larger quantity of shutters in a shorter period. This not only meets the growing demands of the market but also improves overall business profitability.

9. Maintenance and Service

Proper maintenance and service of rolling shutter machines are crucial for their long-term performance and longevity. Regular cleaning, lubrication, and inspection of the machine components are necessary to ensure smooth operation. Additionally, timely servicing by qualified professionals helps identify and address any potential issues, preventing downtime and production delays.

10. The Future of Rolling Shutter Machines

The rolling shutter machine industry continues to evolve, with manufacturers constantly introducing new technologies and features to improve efficiency and product quality. The future of these machines looks promising, with advancements such as AI integration, remote monitoring, and predictive maintenance on the horizon. These developments will further enhance the capabilities of rolling shutter machines and drive the growth of the shutter industry.