Investing in a metal roof machine for sale

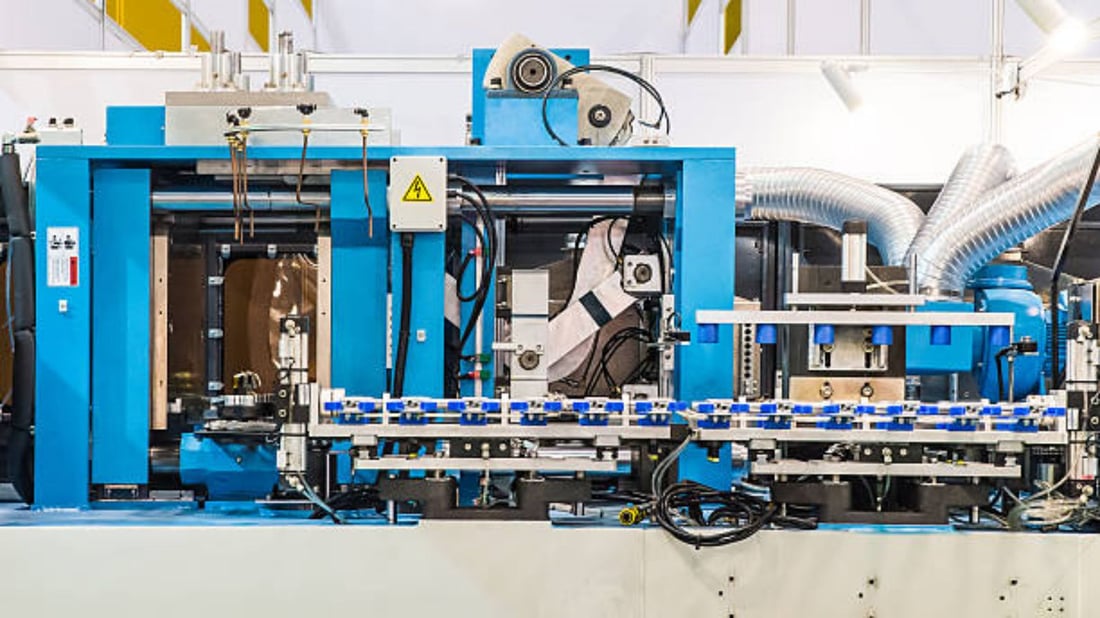

Are you considering purchasing a metal roof machine for sale? If so, you're making a wise decision. Metal roofs have become increasingly popular due to their durability, long lifespan, and energy efficiency. To ensure a seamless installation process, it's crucial to invest in a high-quality metal roof machine. In this article, we will explore the various aspects of metal roof machines for sale, including their benefits, types, features, and factors to consider before making your purchase.

The Benefits of a Metal Roof Machine

Investing in a metal roof machine offers numerous benefits for both contractors and homeowners. First and foremost, it allows for efficient and precise production of metal roof panels, reducing the time and effort required for manual fabrication. Additionally, a metal roof machine guarantees consistent quality and accuracy in each panel, ensuring a seamless fit during installation. These machines are designed to handle a variety of metal materials, such as steel, aluminum, and copper, providing versatility and flexibility for different project requirements.

Types of Metal Roof Machines

When browsing for a metal roof machine for sale, you'll come across various types tailored to specific production needs. The most common types include:

1. Roll Forming Machines

Roll forming machines are widely used in metal roof panel manufacturing. These machines utilize a series of rollers to gradually shape the metal into the desired profile. They are known for their efficiency, high production capacity, and ability to produce panels with complex profiles.

2. Standing Seam Machines

Standing seam machines are specifically designed for fabricating standing seam metal roof panels. These machines create the distinctive raised seams that interlock the panels, providing enhanced weather resistance and durability. Standing seam machines are often utilized for commercial and industrial projects.

3. Portable Roll Formers

Portable roll formers offer flexibility and convenience for on-site metal roof panel fabrication. These machines can be easily transported to the project site, allowing for efficient production without the need for transporting pre-fabricated panels. Portable roll formers are ideal for small-scale projects or repair work.

Key Features to Consider

Before purchasing a metal roof machine, it's crucial to consider certain key features to ensure it meets your specific requirements. Here are some essential features to look for:

1. Material Compatibility

Ensure that the machine is compatible with the type of metal material you plan to use, such as steel, aluminum, or copper. Some machines may have limitations on the thickness or gauge of the metal they can handle.

2. Panel Width and Profile

Determine the maximum panel width and profile options offered by the machine. Consider the specific design requirements of your project and choose a machine that can accommodate them.

3. Production Speed

Production speed is an important factor to consider, especially for large-scale projects. Look for a machine that offers a high production capacity to ensure efficient and timely completion of your metal roof panels.

4. Automation and Controls

Modern metal roof machines often come with advanced automation features and user-friendly controls. These can include touch-screen interfaces, programmable settings, and diagnostic functions that simplify operation and troubleshooting.

5. Warranty and Support

Check for warranty and after-sales support offered by the manufacturer. A reliable warranty ensures that you are protected against any potential defects or malfunctions, while good customer support can assist you in case of any issues or questions that arise during the machine's operation.

Factors to Consider When Buying

When buying a metal roof machine, it's essential to consider several factors to make an informed decision. Here are some key factors to keep in mind:

1. Budget

Set a budget for your metal roof machine purchase and look for options that fall within your allocated budget. Consider the long-term benefits and cost savings that a high-quality machine can offer.

2. Reputation and Reviews

Research the reputation of the manufacturer and read customer reviews to gauge the reliability and performance of the machine. Look for feedback on durability, ease of use, and the overall satisfaction of previous buyers.

3. Training and Support

Consider the availability of training and support provided by the manufacturer. Adequate training ensures that you and your team can operate the machine effectively, while reliable support can assist you in case of any technical issues.

4. Future Expansion

Anticipate your future needs and consider whether the machine can accommodate potential expansion of your business. Investing in a versatile and scalable machine can save you from the need to upgrade or replace it in the near future.

5. Safety Features

Ensure that the machine is equipped with necessary safety features to protect the operators during its operation. This may include emergency stop buttons, safety guards, and interlocking systems.

Conclusion

Investing in a high-quality metal roof machine for sale is a wise decision for contractors and homeowners alike. The benefits of efficiency, precision, and versatility offered by these machines make them indispensable in the metal roofing industry. By considering the different types, key features, and factors to consider, you can make an informed decision and choose the perfect metal roof machine that meets your specific requirements. So, don't hesitate to explore the available options and take your metal roofing projects to new heights!