Metal Roll Formed Profiles: A Comprehensive Guide

Introduction

Metal roll formed profiles are an integral part of many industries, including construction, automotive, and manufacturing. They are commonly used to create customized shapes and designs for various applications. In this article, we will explore the different aspects of metal roll formed profiles, including their uses, advantages, and the process involved in their creation.

The Definition and Purpose of Metal Roll Formed Profiles

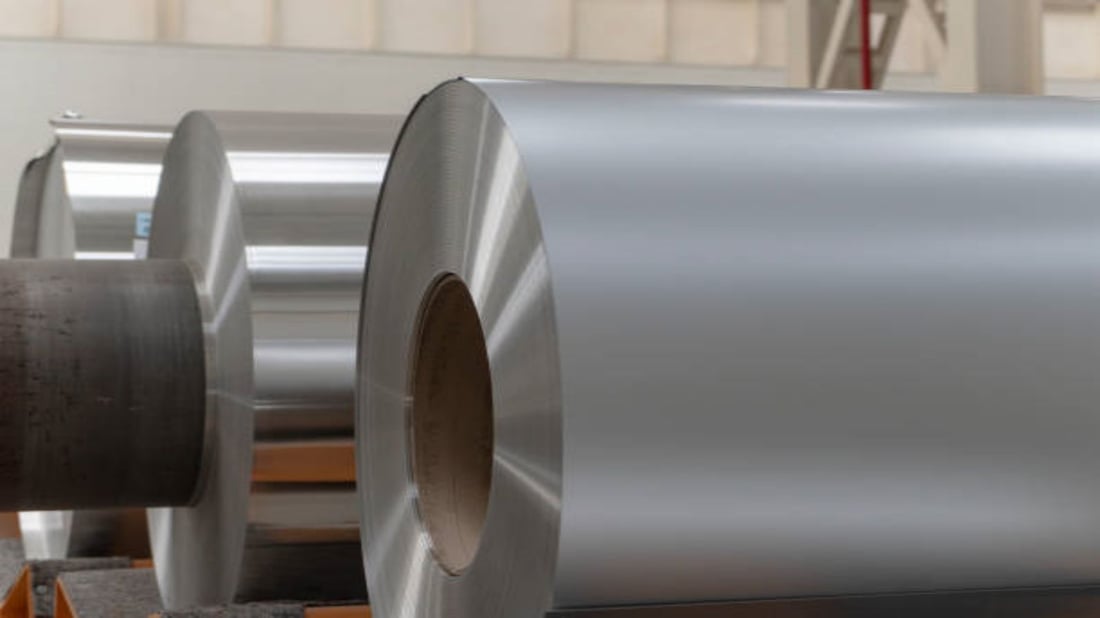

Metal roll formed profiles refer to metal sheets that are shaped into specific profiles through a process called roll forming. Roll forming involves passing a metal coil through a series of rollers to gradually bend and shape it into a desired profile. These profiles can be customized to meet the specific requirements of different industries, making them highly versatile.

Applications of Metal Roll Formed Profiles

Metal roll formed profiles find applications in a wide range of industries. In the construction sector, they are used for roofing, siding, and framing systems. In the automotive industry, they are utilized in the manufacturing of car body parts and structural components. Additionally, metal roll formed profiles are also commonly used in the production of appliances, furniture, shelving systems, and many other products.

The Advantages of Metal Roll Formed Profiles

Metal roll formed profiles offer several advantages over other manufacturing methods. One of the key benefits is their cost-effectiveness. Roll forming allows for high-volume production at a lower cost per unit compared to other techniques. Additionally, the process enables the creation of complex profiles with consistent dimensions and tight tolerances. The strength and durability of metal roll formed profiles also make them a preferred choice for many applications.

The Roll Forming Process

The roll forming process involves several steps. First, a metal coil is fed into a machine that gradually shapes it using a series of rollers. Each roller is responsible for bending the metal to a specific angle or curvature. The process continues until the desired profile is achieved. Once the metal has been shaped, it is often cut to the required length and may undergo further processes such as punching or embossing to add additional features.

Materials Used in Metal Roll Formed Profiles

Metal roll formed profiles can be made from a variety of materials, depending on the intended application. Commonly used metals include steel, aluminum, and stainless steel. The choice of material depends on factors such as strength requirements, corrosion resistance, and the desired aesthetic appearance.

The Importance of Design in Metal Roll Formed Profiles

Design plays a crucial role in the success of metal roll formed profiles. A well-designed profile takes into consideration factors such as the material's properties, the intended application, and the manufacturing process. By optimizing the design, manufacturers can ensure that the final product meets the desired specifications while minimizing production costs and material waste.

The Role of Quality Control in Metal Roll Formed Profiles

Quality control is of utmost importance in the production of metal roll formed profiles. Manufacturers implement various measures to ensure the dimensional accuracy and integrity of the profiles. This includes regular inspections, quality testing, and adherence to industry standards and specifications. By maintaining strict quality control, manufacturers can deliver high-quality profiles that meet the requirements of their customers.

The Future of Metal Roll Formed Profiles

The use of metal roll formed profiles is expected to continue growing in the coming years. Advancements in technology and manufacturing processes will further enhance the capabilities of roll forming. This will allow for the production of even more complex profiles with improved efficiency and precision. As industries continue to seek innovative solutions, metal roll formed profiles will remain a valuable component in the manufacturing landscape.

Conclusion

Metal roll formed profiles offer a versatile and cost-effective solution for various industrial applications. Their ability to be customized, along with their strength and durability, make them highly desirable in industries such as construction, automotive, and manufacturing. By understanding the roll forming process and the importance of design and quality control, manufacturers can produce high-quality profiles that meet the specific needs of their customers.