The Advantages of a flashing roll forming machine

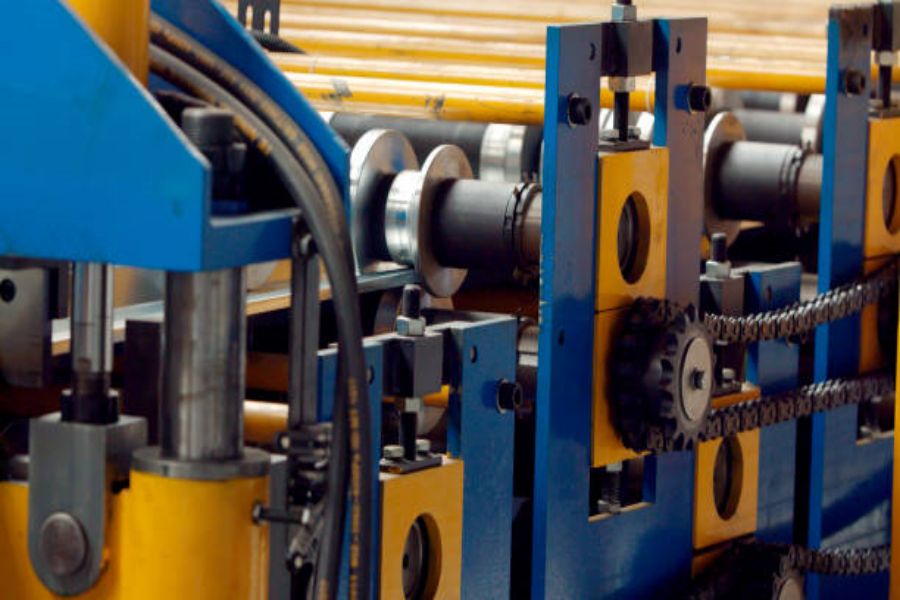

A flashing roll forming machine is a versatile piece of equipment that plays a crucial role in the production of metal flashing. Metal flashing is used in various industries, including construction, automotive, and aerospace, for applications such as weatherproofing, sealing, and protecting structures and components. This article will explore the key advantages of using a flashing roll forming machine, from its efficiency and precision to its cost-effectiveness and versatility.

Efficiency and Precision in Production

One of the primary advantages of a flashing roll forming machine is its efficiency and precision in the production process. This machine can continuously feed and form metal coils into desired shapes and profiles, allowing for high-speed and consistent production. With computer-controlled systems, the machine ensures precise measurements and accurate forming, minimizing material waste and errors.

Cost-Effectiveness and Material Savings

Investing in a flashing roll forming machine can bring significant cost savings in the long run. By eliminating the need for manual labor and reducing material waste, the machine helps optimize production costs. The precision of the machine ensures that each piece of flashing is formed with minimal material usage, maximizing material savings and reducing overall production costs.

Versatility in Forming Profiles

A flashing roll forming machine offers great versatility in forming various profiles and shapes. It can be programmed to produce a wide range of flashing profiles, including L-shaped, U-shaped, T-shaped, and custom designs. This versatility allows manufacturers to meet diverse customer requirements and expand their product offerings without the need for additional equipment.

High-Quality and Consistent Output

With a flashing roll forming machine, manufacturers can achieve high-quality and consistent output. The machine's precision and automated processes ensure that each piece of flashing is formed with the same specifications and quality. This consistency is essential for meeting industry standards and customer expectations, ultimately enhancing the reputation and reliability of the manufacturer.

Time-Saving and Increased Productivity

By automating the production process, a flashing roll forming machine significantly saves time and increases productivity. It eliminates the need for manual labor, allowing operators to focus on other tasks while the machine continues to produce flashing. Moreover, the high-speed capabilities of the machine enable manufacturers to meet tight deadlines and handle large production volumes efficiently.

Enhanced Safety for Operators

Flashing roll forming machines are designed with operator safety in mind. They come equipped with safety features such as emergency stop buttons, protective guards, and safety interlocks. These measures ensure that operators can work in a safe environment, minimizing the risk of accidents and injuries during the production process.

Easy Setup and Operation

Despite their complexity, flashing roll forming machines are designed for easy setup and operation. Most machines feature user-friendly interfaces and intuitive controls, allowing operators to quickly learn and operate the equipment. Additionally, the machines can store multiple profiles and settings, making it easy to switch between different products and configurations.

Reliability and Longevity

Investing in a high-quality flashing roll forming machine guarantees reliability and longevity. These machines are built to withstand heavy use and demanding production environments. With proper maintenance and regular servicing, a well-maintained machine can operate efficiently for many years, providing a consistent and reliable production solution.

Integration with Automation Systems

Flashing roll forming machines can be integrated into larger automation systems, further enhancing their capabilities and productivity. Integration allows for seamless material handling, product tracking, and quality control. It enables manufacturers to streamline their production processes and achieve higher levels of efficiency and automation.